Understanding Transmission Belts: Types, Functions, and Applications

Different mechanical systems require transmission belts to transfer power among rotating shafts. Notably, these are important elements that facilitate the mechanical functionality of various sectors such as automobile production, manufacturing and agriculture industries.

Types of Transmission Belts

V-Belts: These are some of the most commonly used transmission belts. They have a V-shaped cross section which gives them high frictional properties and grip. The reason why they are very common is their effectiveness in transferring power between pulleys in car engines industrial machinery and air conditioning units.

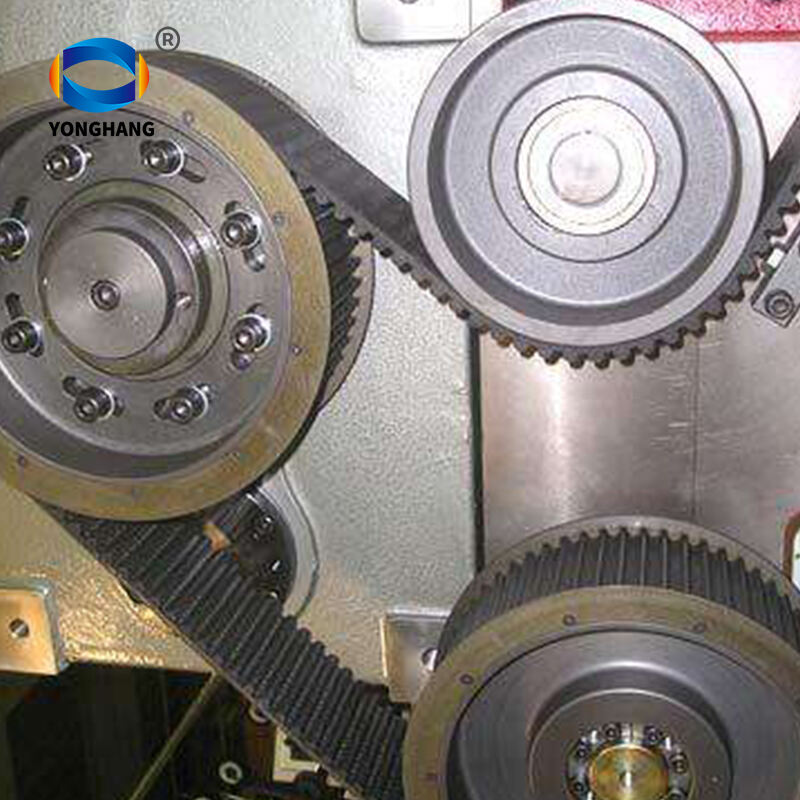

Timing Belts: Timing belts or synchronous belts have teeth on the inside surface that mesh with those found on the pulleys. In this way, when two or more things rotate at different speeds, they always do so at the same time. Mostly they are used for accurate power transmissions in engines and conveyor systems for instance.

Functions of Transmission Belts

Power Transfer: It is through transmission belts that machines can convert one turning shaft into another to execute their intended purposes. That is why it is essential because it changes engine or motor-mechanical-energy into useful energy for other applications.

Speed Control: Transmission belts help to regulate the speed of machinery by altering either the size of pulleys or the tension in the belt used. When there is need for accurate control over operational speeds, this aspect becomes crucial.

Vibration Damping: The purpose of transmission belts is to absorb shocks and vibrations that come from operating machines. This function ensures less wear on components of machines as well as system durability.

Applications of Transmission Belts

Automotive Industry: In vehicles, transmission belts are used in engines to drive accessories such as alternators, water pumps, and air conditioning compressors. A connecting link between camshaft and crankshaft called a timing belt plays an especially important role.

Industrial Machinery: Transmission belts are used in different industries which include conveyor systems, packaging plants and manufacturing machinery among others because they enable efficient movement of materials within production lines.

Agricultural Equipment: In farming, transmission belts are employed into machine like tractors combines balers among others to drive essential functions and attachments thus ensuring smooth running farm equipment.

Transmission belts are forces in many mechanical systems, which give dependable power transmission, speed variation and shock absorption. Transmission belts keep evolving as technology advances so as to enhance their performances and applications in a variety of industries.

EN

EN

AR

AR

HR

HR

DA

DA

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

SR

SR

SK

SK

UK

UK

VI

VI

TH

TH

TR

TR

AF

AF

MS

MS

IS

IS

HY

HY

AZ

AZ

KA

KA

BN

BN

LA

LA

MR

MR

MY

MY

KK

KK

UZ

UZ

KY

KY