The Multi-functionality and Accuracy of PU Timing Belts in Contemporary Industrial Applications.

In the complex world of current industrial machines, accuracy and strength are key factors to guaranteeing efficient operations as well as maximum productivity. Polyurethane (PU) Timing Belts are one of the many items that make this possible through their exceptional mechanical characteristics, precise control features and a wide range of uses.

Understanding PU Timing Belts

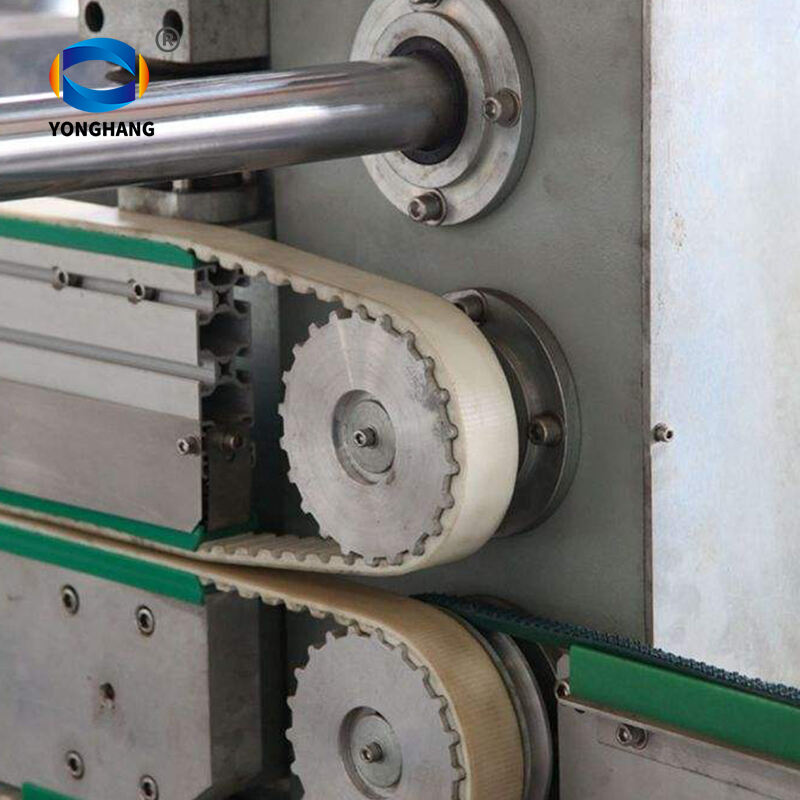

The materials used to make these timing belts, PU Timing Belts made out of high-quality polyurethane, are meant to transmit rotating motion from one or more shafts at particular intervals. Made with specific tooth profiles through which they use polyurethane’s qualities like high elasticity and robustness, these belts can run with very low backlashes and therefore very accurate. This makes them different from conventional mechanisms for transmitting power even when it comes to exact timekeeping and harmonization.

Key Features of PU Timing Belts

Polymer Chain Flexibility: Polyurethane is inherently resistant to wear; therefore PU Timing Belts can work under heavy loads without getting worn out quickly hence last long in service.

Almost Quiet Action: For less vibration and noise while working on the belt, there is smooth contact b/n its teeth plus sprocket teeth.

Precision and Synchronization: PU Timing Belts have low backlash characteristics as well as precise tooth pitch enabling them to which is crucial in the case of high-precision machinery.

Chemical Resistance: Polyurethane’s resistance against oils, greases and some chemicals makes PU Timing Belts ideal for use in harsh conditions.

Dynamic Flexibility: In addition, the elasticity of the material allows them to respond to changes in tension or misalignment thereby reducing stress on drive systems.

Advantages in Industrial Applications

Increased Efficiency: Improved energy efficiency arises from the precision timing and reduced friction that comes with using PU Timing Belts leading to reduced operating costs.

Reduced Maintenance: Low wear characteristic and long lasting make PU belts less costly since there frequent replacements are not necessary when compared to other belts; thus saving time and resources.

Environmentally Friendly: Apart from being relatively eco-friendly, this is also a step towards reducing waste that comes with frequent changeover of worn out belts which delays their disposal hence increasing pollution levels.

Applications Across Industries

PU Timing Belts find their place in numerous industries, including but not limited to:

Automotive: Engine timing, transmission belt as well as other critical components give it precise power transmission.

Printing and Packaging: Registration accuracy during high speed printing presses as well as packaging machines.

EN

EN

AR

AR

HR

HR

DA

DA

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

SR

SR

SK

SK

UK

UK

VI

VI

TH

TH

TR

TR

AF

AF

MS

MS

IS

IS

HY

HY

AZ

AZ

KA

KA

BN

BN

LA

LA

MR

MR

MY

MY

KK

KK

UZ

UZ

KY

KY