Vacuum Timing belts coated for Rovema VFFS packer

From liquids to solids, powders to particles, agricultural products to perishables, vertical molding-filling sealers

(VFFS) play an important role in packaging applications, keeping items fresh for use and consumption.

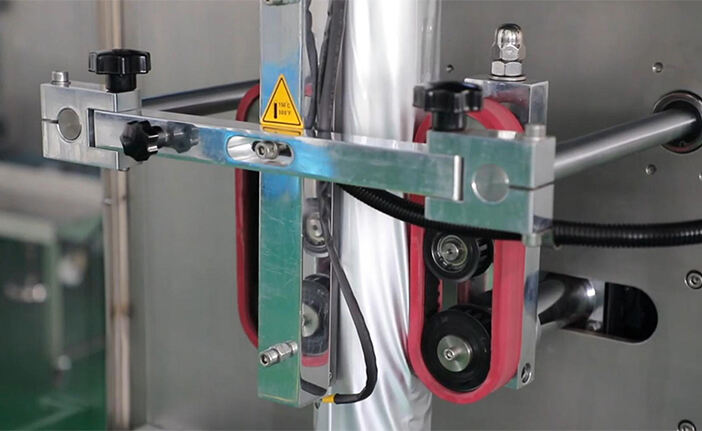

Machine manufacturers who design, develop, and deliver such equipment face many challenges. VFFS packaging

machine film conveyor belts play a critical role in the molding process, and we are responsible for adding glue

and PU to the surface of these toothed Timing belt coated help pull the film vertically down in the package to

make bags. Not only do we offer seamless Timing belt coated with surface slots with PU/coated , but we can also

provide belt slotting holes.

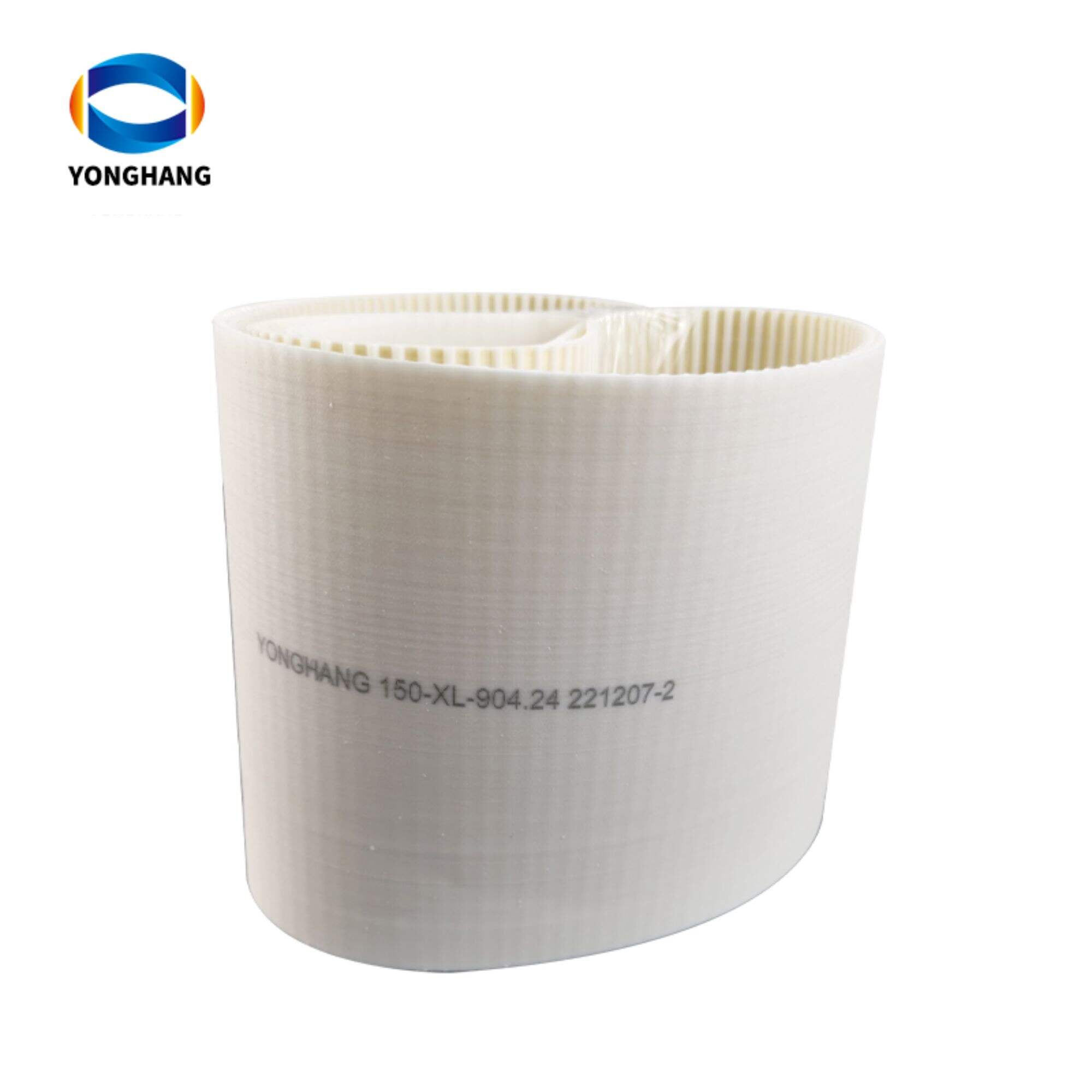

Timing belts coated band: The base band can be either a urethane Timing belt or a rubber seamless Timing belt.

Timing belt- surface coated: rubber with a hardness of 40ShA or a 60ShA polyurethane PU.

Timing belts coated-holes and grooves: customized after measuring the aperture of the strap and surface, some

of the holes are reverse-sinked, such as the Rovema belt;Timing belts coated -face machining: Measures toothless

areas, many belts have toothless areas on the tooth side to allow the belt to operate above the vacuum bed.

EN

EN

AR

AR

HR

HR

DA

DA

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

SR

SR

SK

SK

UK

UK

VI

VI

TH

TH

TR

TR

AF

AF

MS

MS

IS

IS

HY

HY

AZ

AZ

KA

KA

BN

BN

LA

LA

MR

MR

MY

MY

KK

KK

UZ

UZ

KY

KY