Understanding Timing Belts: Essential Components for Engine Performance

Timing belts are one of the most important elements in operational combustion engines because they ensure that the crankshaft and camshaft are always in perfect sync.

What Is a Timing Belt?

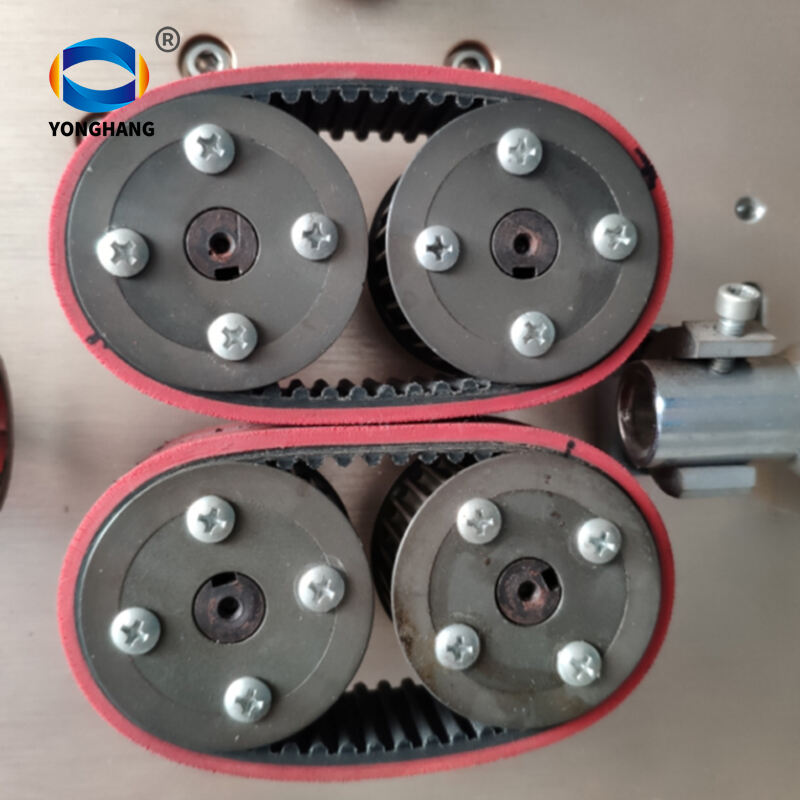

A timing belt is a reinforced rubber belt that links an engine’s crankshaft to its camshaft. It guarantees that during each intake and exhaust stroke of each cylinder, the valves of the engine open and close at appropriate times. Perfect timing is vital for efficient engine performance and preventing mechanical breakdowns.

Functions of a Timing Belt

Synchronization: The main function of a timing belt is to synchronize the rotation of the crankshaft and camshaft. This positioning guarantees that when pistons move up and down, engine valves respond accordingly.

Preventing Engine Damage: Properly timed pistons will not hit valves, thus preventing any grave destructions on an engine. Therefore, keeping this coordination through a timing belt has great value in the life span of an engine.

Driving Other Components: In some engines, there may be other components driven by the timing belt such as water pumps which help cool down engines. This extra activity shows how central is a timing belt within every operation undertaken by an engine in general.

TYPES OF TIMING BELTS

Standard Rubber Timing Belts: These are the most common rubber belts made from reinforced with fibers. They are budget-friendly and ideal for many normal car engines.

Steel Reinforced Timing Belts: For added strength and durability, these belts have steel cords as a component of their construction. In high performance or intense duty engines that require additional reliability, they are usually put into use.

Composite Timing Belts: Composite belts use state-of-the-art materials to enhance its performance in terms of resistance to wear compared to temperature fluctuations.

MAINTENANCE AND REPLACEMENT

Regular Inspections: From time to time, look for signs of wear on the timing belt such as cracking or fraying.

Manufacturer’s Recommendations: Follow the manufacturer’s schedule at which you should replace your timing belt as per his recommendations. Usually, timing belts should be changed within 60,000 - 100,000 miles but this may vary depending on the model of vehicle and driving conditions.

Professional Service: Very often it is necessary to hire an expert when it comes to timing belt replacement since it is quite a complex operation for any mechanic who does not have enough experience in this area. The correct fitting is essential if engine damage is going to be prevented and optimal performance assured.

IMPORTANCE OF TIMING BELT MAINTENANCE

Engine Performance: For better fuel economy and lower emissions through smooth running of engine efficiency can only happen under well-maintained timing belt scenario

Stopping Breakdowns: Regular upholding and timely changing of timing belt save engine failures and expensive repairs.

These belts are essential for the smooth running of internal combustion engines, as they play a crucial role in coordinating components of the machine and protecting them from injuries.Regular checks and prompt replacement help maintain efficiency of an engine while preventing expensive repairs.

EN

EN

AR

AR

HR

HR

DA

DA

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

SR

SR

SK

SK

UK

UK

VI

VI

TH

TH

TR

TR

AF

AF

MS

MS

IS

IS

HY

HY

AZ

AZ

KA

KA

BN

BN

LA

LA

MR

MR

MY

MY

KK

KK

UZ

UZ

KY

KY