Timing Belt Coating: Improving its Durability and Efficiency

In the automotive and industrial sectors, timing belt coatings serve critical purposes in optimization and protection of the timing belts. Through the use of coatings, manufacturers of such belts are able to increase the belts' resistance to wear, heat, and other factors, which assures reliable operation and gives prolongs the service life.

Features of Timing Belt Coating

Enhanced Durability: In order to offer better performance, timing belt coatings have been developed so that they improve the lifespan of these belts. This includes exposure of the coatings to abrasion, chemistries and physical environment in high stress applications.

Heat Resistance: Coatings help to a major extent protect a timing belt from high temperatures. It is critical in automobile engines and any industrial equipment that subjects the belt to extreme temperatures that can make the belt fails quickly.

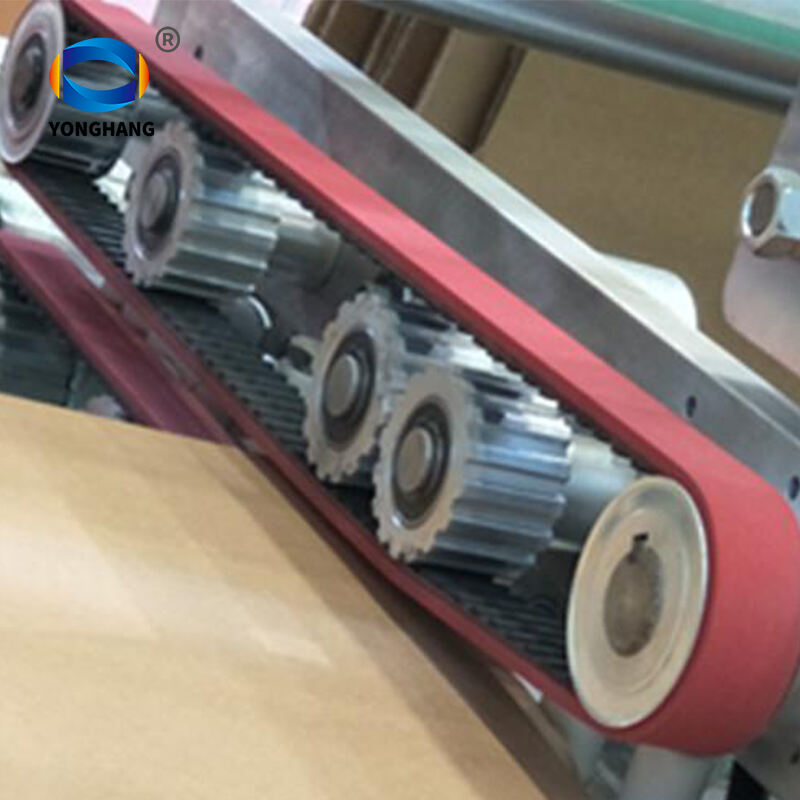

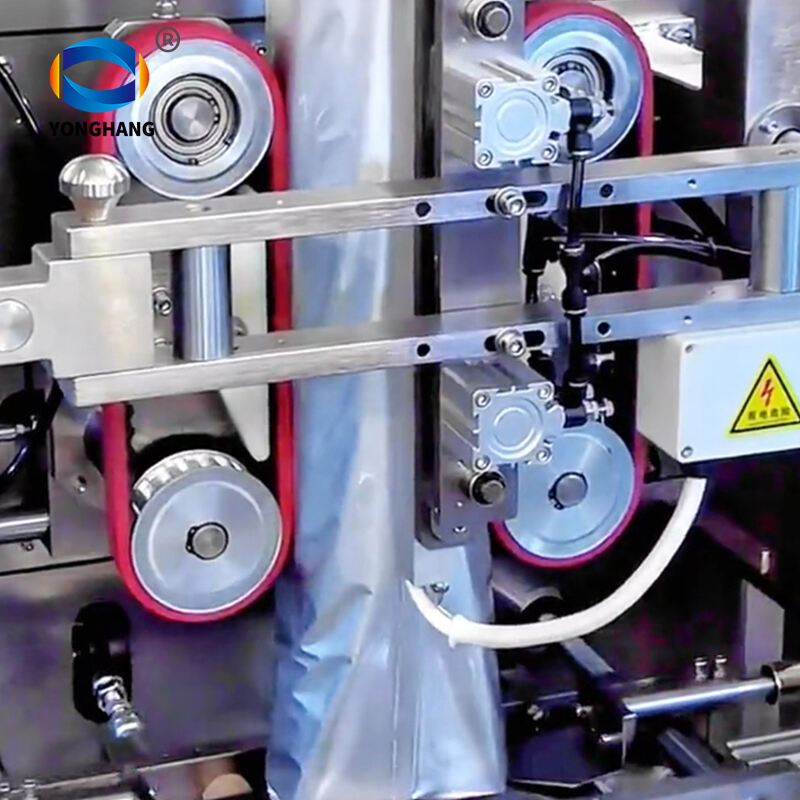

Friction Reduction: It is possible to attach special coatings which reduce the friction of the contacting (timing) belts and pulleys or gears. This will help to enhance efficiency and enhance performance in addition to making lower energy use.

Chemical Resistance: Timing belt coatings offer protection from oils and other solvents which are of concern to belts. This is very important when the belts are used in certain harsh environments wherein such substances are prevalent irrespective.

Performance Improvement: Thanks to coatings, the work of the timing belt is carried out over a longer period without broadening and slipping, ensuring that the machinery or engine components retain correct timing and proper functionality.

Benefits

Longer Service Life: Coatings for timing belts have been designed to also counter environmental effects and physical damage thus among other factors, their lifespan has also increased considerably lowering the replacement and maintenance costs.

Higher Performance: The use of less friction and improved resistive heat translates to better overall performance of the system with lower expenses.

Economical: The coated timing belt will naturally bear higher initial expenditure if purchased, however, there will be changes in the maintenance practices as the belts will have lower frequencies and the system is cost-efficient in the long run.

Dependability: Usually, coated timing belts operate more reliably, a trait that is necessary not only for automotive timing belts but also for industrial timing belts. This reliability facilitates smooth operations, reducing incidences of operational failures that were not anticipated.

Conclusion

Coatings on timing belts are crucial in improving the lifespan and performance of timing belts across various applications. Such coatings maximize the performance and durability of the timing belts by improving the heat resistance, decreasing the friction as well as providing protection from chemicals and abrasive wear. For both the automotive industry as well as the industrial segment, it is proven that there is a payback in terms of efficiency, cost reduction, and dependability when coated timing belts are utilized.

EN

EN

AR

AR

HR

HR

DA

DA

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

SR

SR

SK

SK

UK

UK

VI

VI

TH

TH

TR

TR

AF

AF

MS

MS

IS

IS

HY

HY

AZ

AZ

KA

KA

BN

BN

LA

LA

MR

MR

MY

MY

KK

KK

UZ

UZ

KY

KY