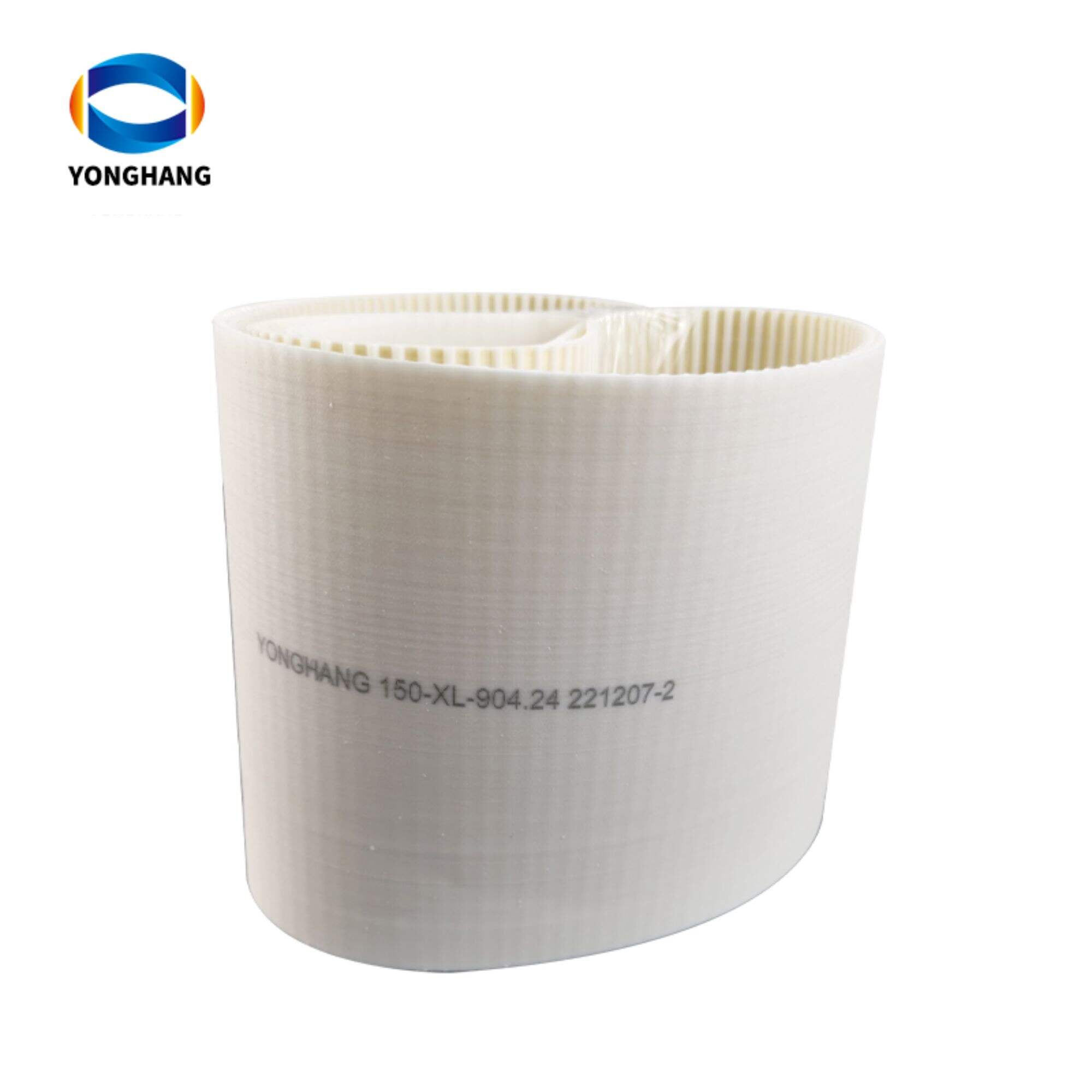

Precision Reinforced APL Rubber Timing Belt for Inlet & Outlet Conveyors of Glass Edging Machine, Mitering & Beveling Machines

Glass grinding machine APL Rubber Timing Belt is a transmission device, mainly used in the glass, ceramic industry grinding machinery! In many mechanical equipment is used in this transmission method, the reason why it will be used in the transmission of many devices, the main reason is that it is thought to be able to achieve very good transmission effect, in the transmission of a combination of the respective advantages of other transmission belts. Said glass grinding machine synchronous belt integrated with the respective advantages of other transmission, because it is by an inner circumference of the surface with equally spaced teeth ring line belt and has a corresponding coincident wheel, with such a mechanism and the application of the working principle, on the integrated belt drive, chain drive and gear transmission of their respective advantages. In the use of synchronous belt rotation, will be through the belt teeth and wheel groove meshing to transmit power, the transmission must have a very accurate ratio, will not appear no slip, can obtain a constant speed ratio, the transmission effect is very smooth, but also to absorb vibration to reduce noise, the transmission ratio range will also be very large.

The Glass grinding machine APL Rubber Timing Belt does integrate the respective advantages of other transmission, with these advantages, it can present a very good transmission effect when used, glass grinding machine synchronous belt using high-quality thermoplastic polyurethane (PU) material and high-strength wire core, produced through a special molding process, with wear and shear resistance! Because the synchronous belt surface is relatively smooth and the pu material itself is relatively hard (general PU synchronous belt hardness in Shore 90 ° ~ 95 ° or so), so usually add a layer of rubber or APL red rubber on the surface, can also add dark green pattern, all kinds of models can be customized!

EN

EN

AR

AR

HR

HR

DA

DA

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

SR

SR

SK

SK

UK

UK

VI

VI

TH

TH

TR

TR

AF

AF

MS

MS

IS

IS

HY

HY

AZ

AZ

KA

KA

BN

BN

LA

LA

MR

MR

MY

MY

KK

KK

UZ

UZ

KY

KY