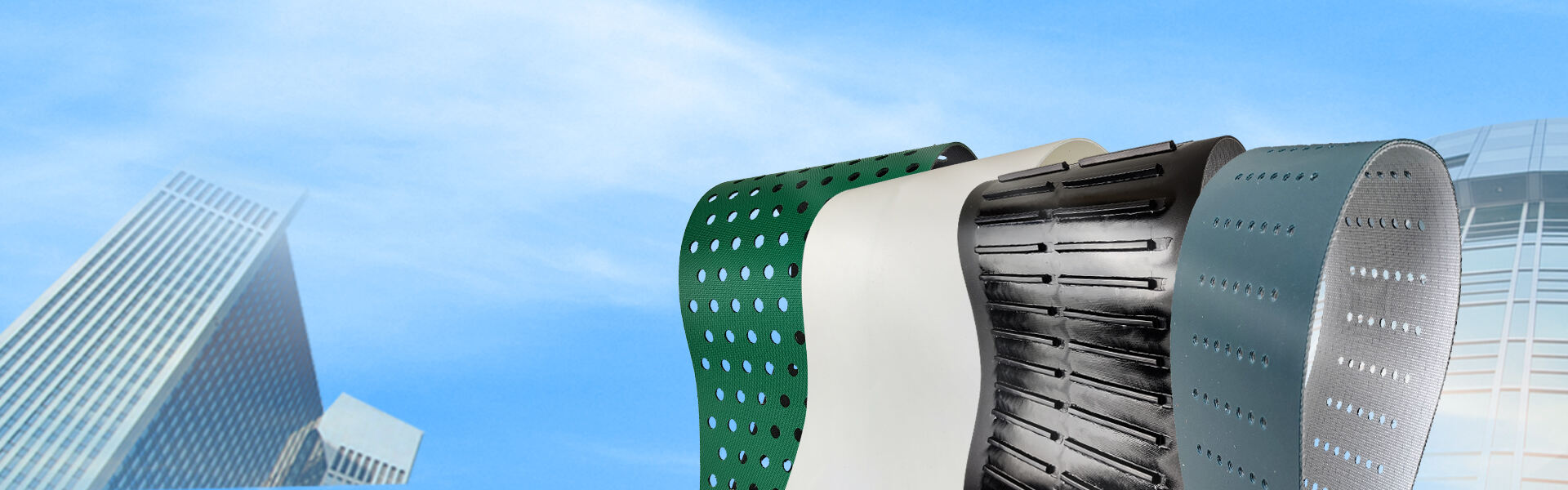

Conveyor Belts

The conveyor belt is a material handling system designed to move supplies, materials, and components using an efficient and effortless process that saves on time, energy, and cost.

Applications include power transmission, conveying, driving, indexing, linear drive and others. Industries include machine engineering, agricultural engineering, automotive industry, household industry and others.

Material: rubber, PVC, PU, silicone, etc., performance: heat resistance, high temperature, easy to clean, etc.

- Introduction

Introduction

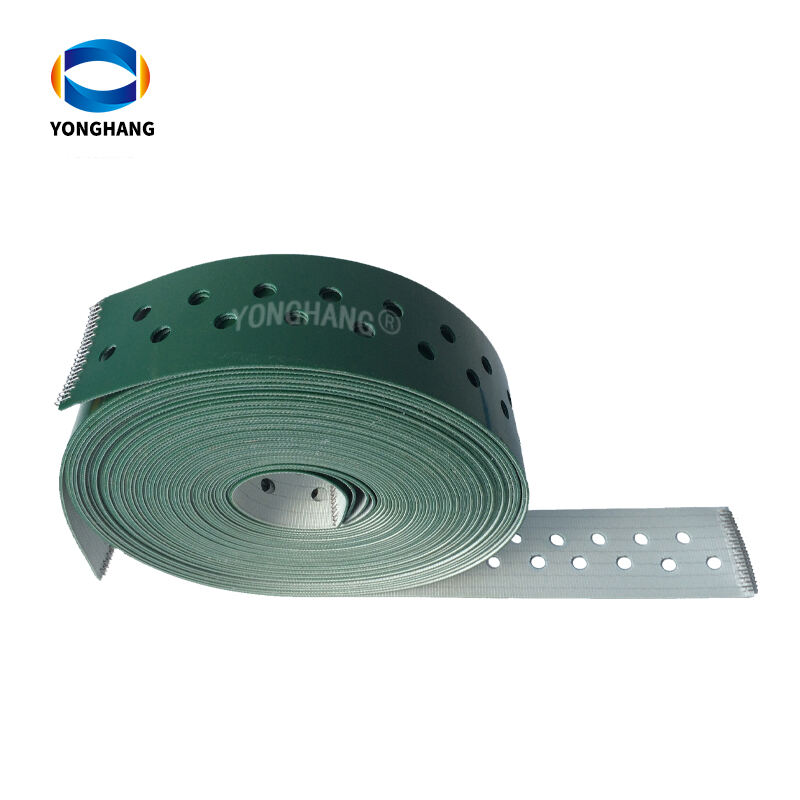

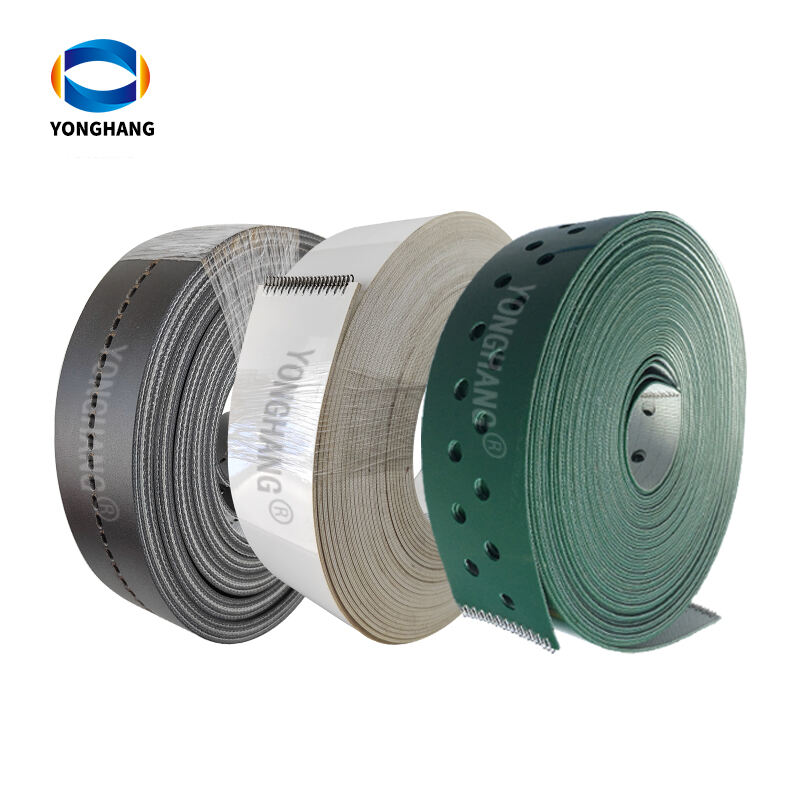

Polyvinyl Chloride (PVC) conveyor belts are standard belts in the food industry that can be used for basic applications across food processing and handling.

PVC has grown to become the third most widely produced plastic, known for its durability and ease of use. A PVC-coated conveyor belt is best suitable for materials handling, bakery production applications, and meat, fish, and dairy processing.

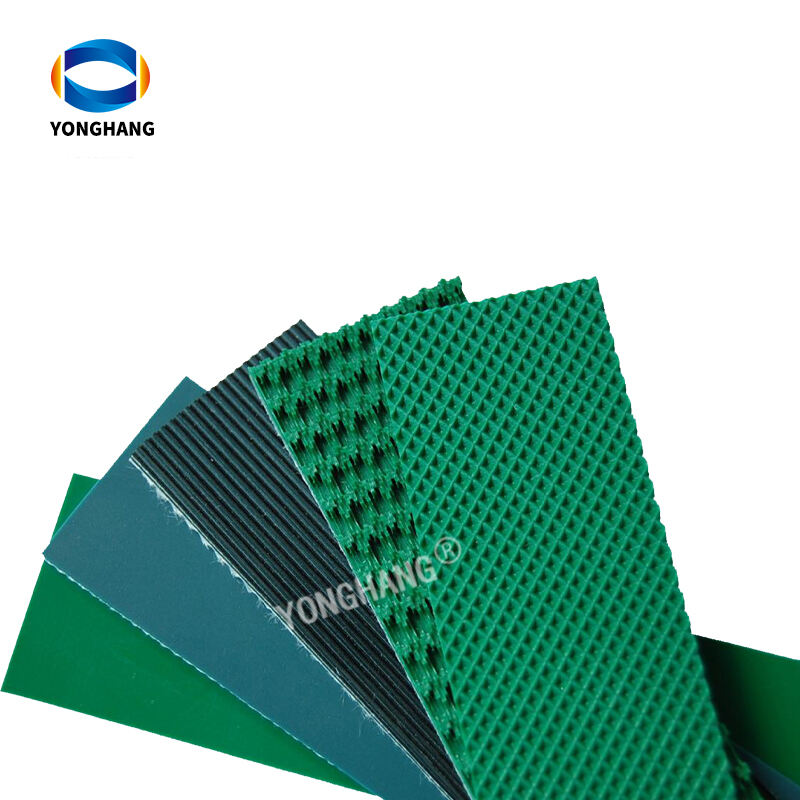

PVC conveyor belts have a synthetic fiber canvas as a core, PVC plastic covering, conveying light weight or medium weight of a type of conveyor belt. The synthetic fiber cores used in this belt are polyester, nylon, Velen, carbon fiber and the like. The PVC belt is generally made of 1 to 3 layers of fabric, each fabric thickness 0.5 ~ 0.8 mm.

One of the main advantages of PVC conveyor belts is a wide range of performances bearing surface of the tape. In recent years, it has been widely used in PVC light conveyor belts because of its high strength, small elongation and good temperature resistance.

These antistatic PVC belts provide good chemical resistance and are resistant to hot water and steam, as well. Based on specific needs and conveyor belt manufacturers, there are also flame-retardant models available.

With limited abrasion resistance and limited resistance to solvents, oil, and grease, PVC belts are best suited for processing of fruits and vegetables and simpler operations with limited special requirements.

For those unaware of specifications for their food processing, PVC belts are a reliable choice and favorable in price compared to other conveyor belts.

PU conveyor belts are resistant to oil, corrosion, cold and cutting. Polyurethane (PU) conveyor belts use specially treated high-strength synthetic polyurethane fabric as the carrier skeleton, and the coating layer is made of polyurethane (PU) resin. It has the characteristics of high tensile strength, good winding, lightness, thinness and toughness, but is also oil resistant, non-toxic, hygienic and easy to clean. The conveyor belt is fully compliant with US FDA hygiene standards and is resistant to abrasion and physical ageing, making it a durable conveyor product.

EN

EN

AR

AR

HR

HR

DA

DA

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

SR

SR

SK

SK

UK

UK

VI

VI

TH

TH

TR

TR

AF

AF

MS

MS

IS

IS

HY

HY

AZ

AZ

KA

KA

BN

BN

LA

LA

MR

MR

MY

MY

KK

KK

UZ

UZ

KY

KY