PU Timing belts with cleats (also known as profiles) allow for innovative design solutions for dividing, stepping

and positioning. They are made of the same abrasion resistant polyurethane as the timing belts. For whatever

conveying purpose we can attach them in any desired number or sequence.

For example: push, ship or start in packaging systems, product placement systems, etc., all of which require

timing belt with cleats!

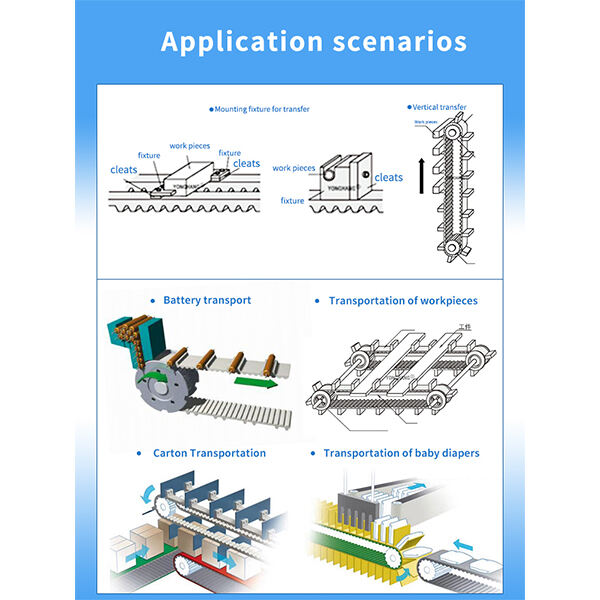

1. According to the size and shape of the conveyor product, the suitable size cleats are processed on the back

of the sync belt to protect the product from dropping when conveying the product.

2. Can be accurately located, such as the transmitter belt of the code press, in a certain distance there is a sensing

requirements, can be customized.according to the required distance cleats, which can play an accurate role in sensing.

3. According to different material sizes to choose different cleats specifications, can be fixed, storage of materials,

play an alternate delivery of products to separate the role.

These are the three main uses of timing belt with cleats, you can choose the right bezel type and size for your own

use when purchasing to meet different production needs! With 10 years of industry production experience, Yonghang

specializes in a wide range of synchronous with special processing timing belt with cleats, which can be customized

to the needs of customers in a variety of different types, different spacing, different sizes of cleats .

EN

EN

AR

AR

HR

HR

DA

DA

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

SR

SR

SK

SK

UK

UK

VI

VI

TH

TH

TR

TR

AF

AF

MS

MS

IS

IS

HY

HY

AZ

AZ

KA

KA

BN

BN

LA

LA

MR

MR

MY

MY

KK

KK

UZ

UZ

KY

KY