Chain Sprocket

YONGHANG Sprocket wheel is a kind of wheel with embedded fastening teeth, used to engage with the pitch accurate block on the chain link ring or cable. Chain wheel is widely used in chemical industry, textile machinery, escalators, wood processing, three-dimensional parking garage, agricultural machinery, food processing, instrumentation, petroleum and other industries such as mechanical transmission.

- Introduction

Introduction

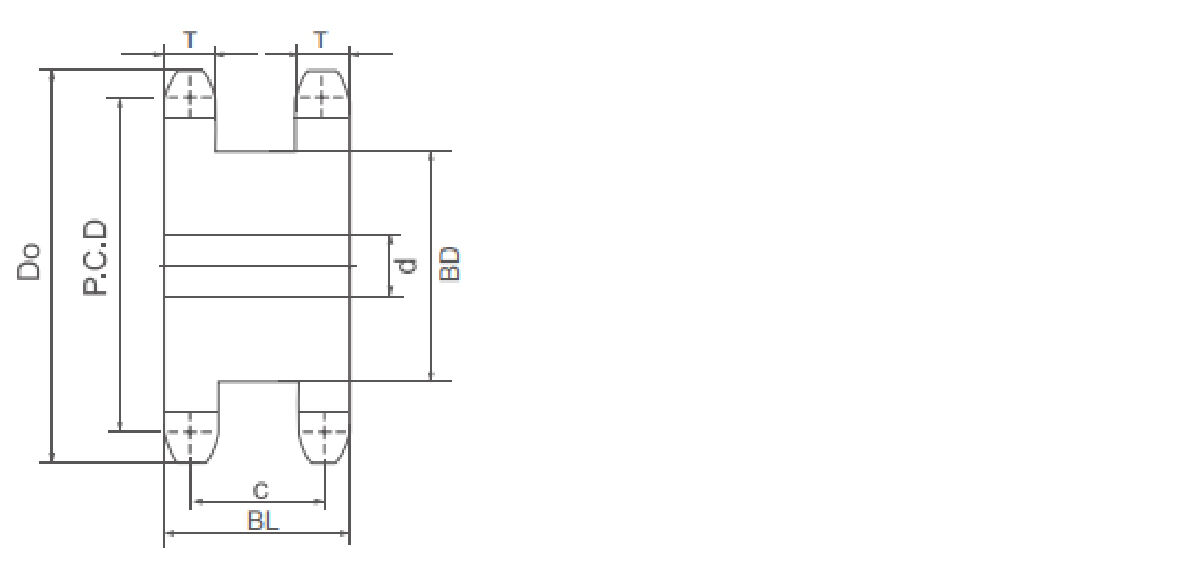

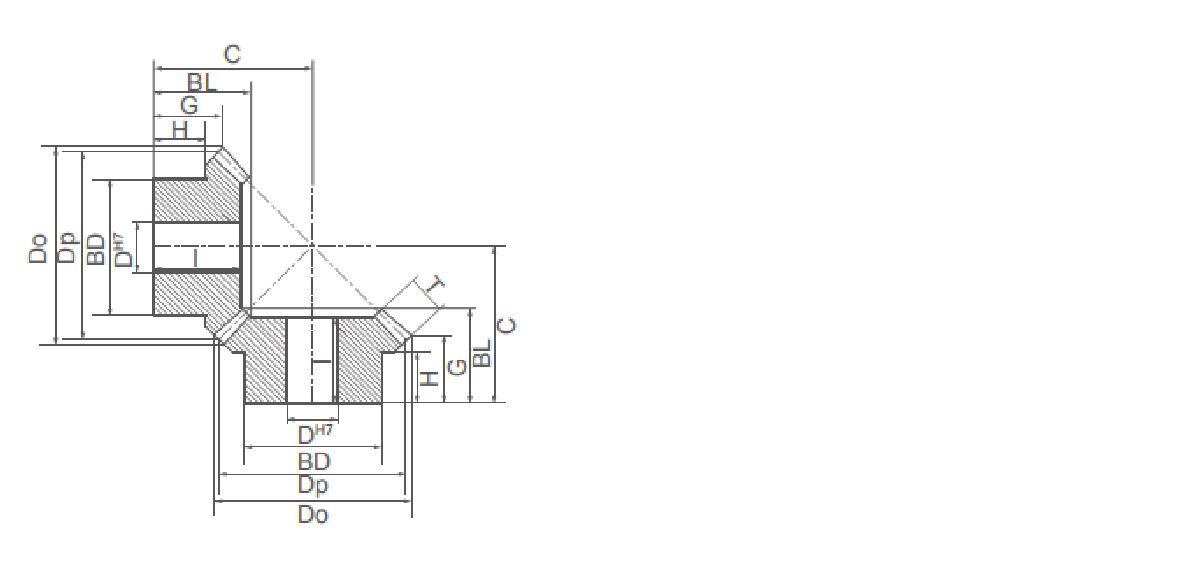

Standard Hole Sprockets

Standard Hole SprocketAll models of sprockets are made of high quality 45 steel, can be customized stainless steel SUS304; conform to JS/DIN specifications, widely used in agriculture, logistics, food processing, packaging, three-dimensional garage, printing and other industries, such as mechanical transmission, etc. Sprocket teeth high-frequency quenching, tempering, to improve the strength of the tooth end and wear life.

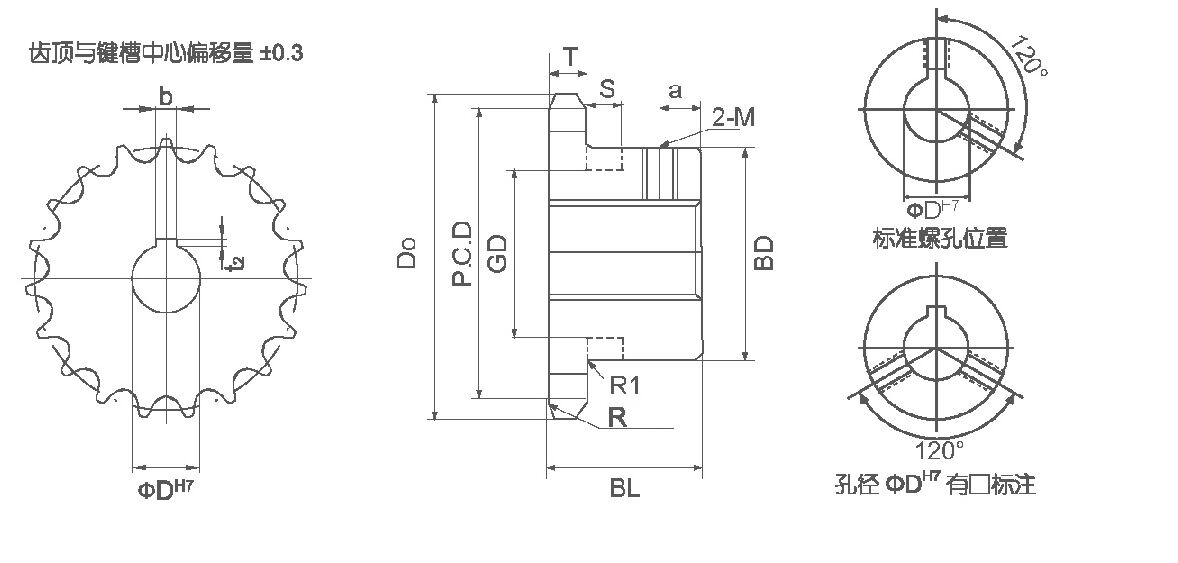

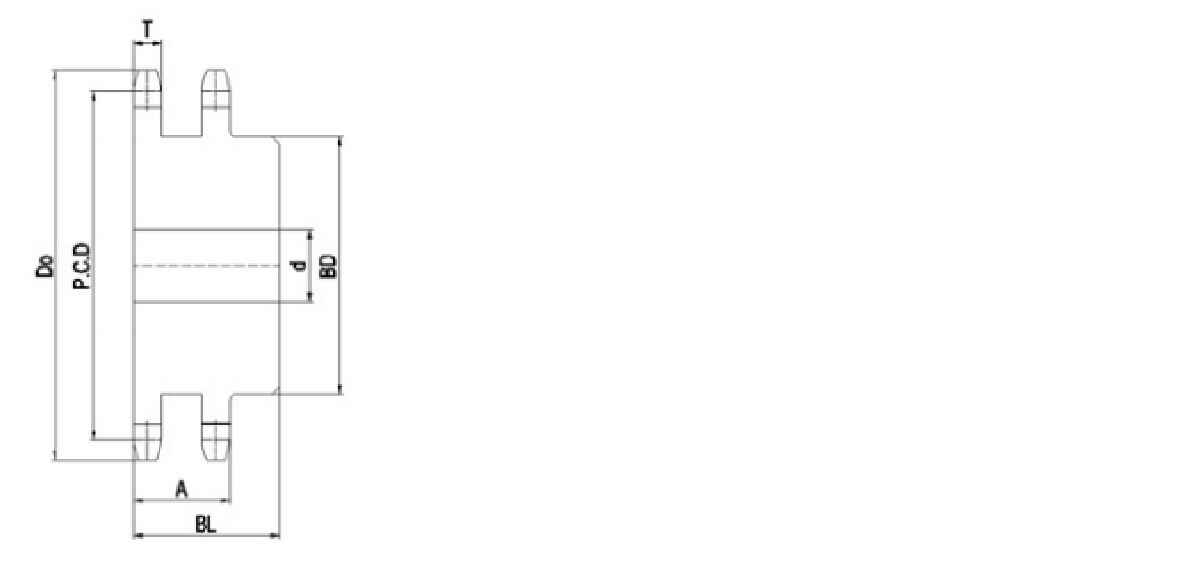

Finished Bore Sprockets

Finished bores, keyways and screw holes can be supplied as machined finished products, so that customers can use them immediately without further processing. Shaft bores, keyways and screw holes, surface treatments, etc. can also be customised according to customer requirements.

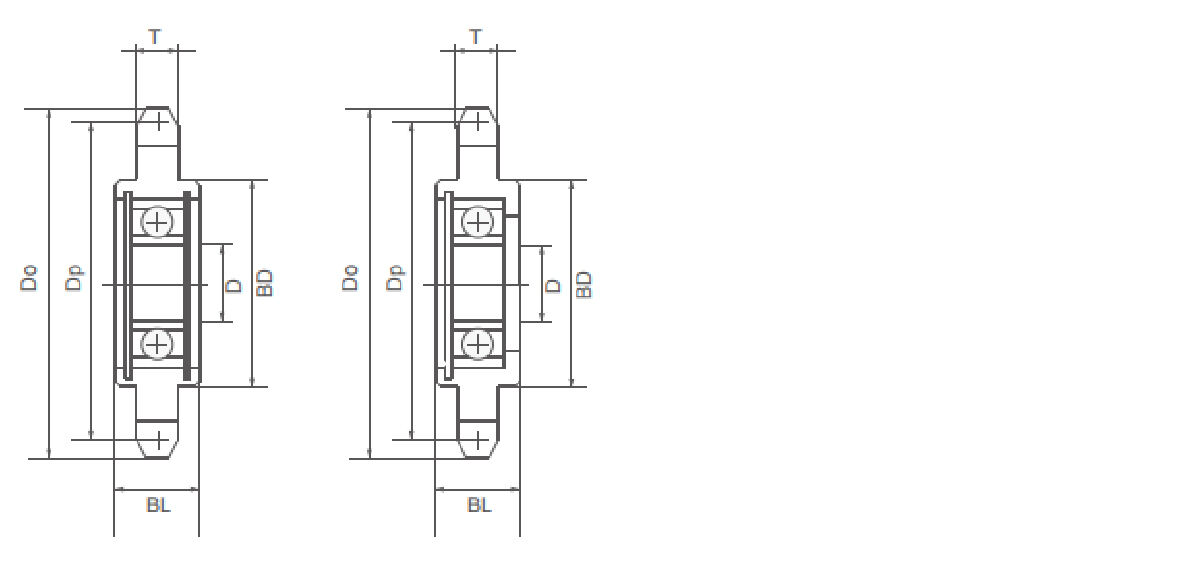

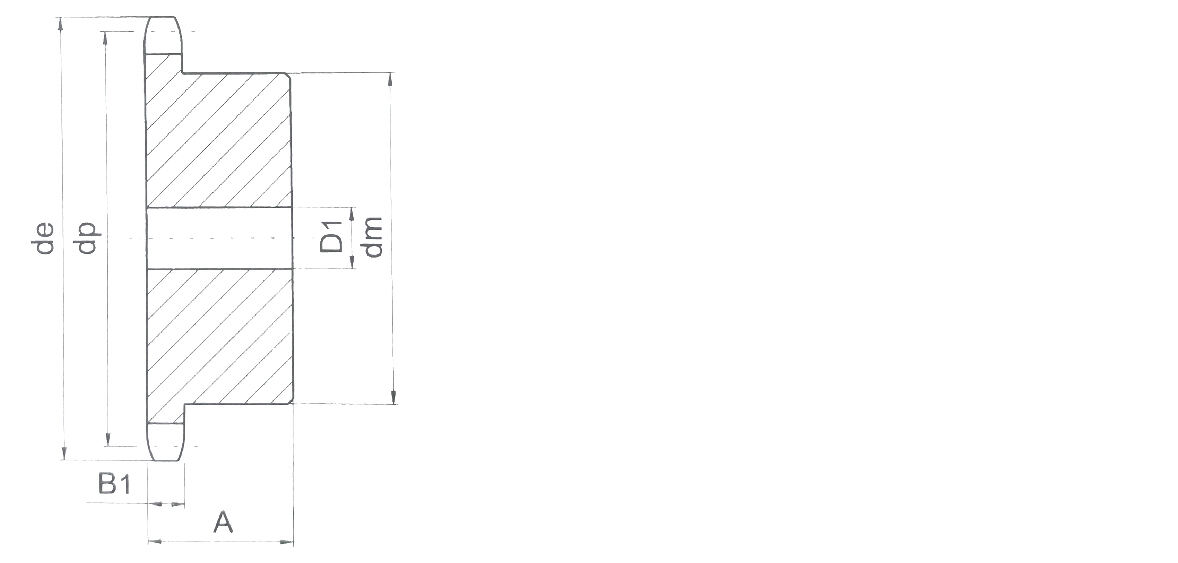

Double Drive Sprockets

Standard A type single chain double row sprocket is designed for two single row chains. The sprockets are manufactured from high quality 45" carbon steel and the teeth are hardened. The actual bore diameter depends on the usual mechanical design and the key fit is also determined by the design requirements.

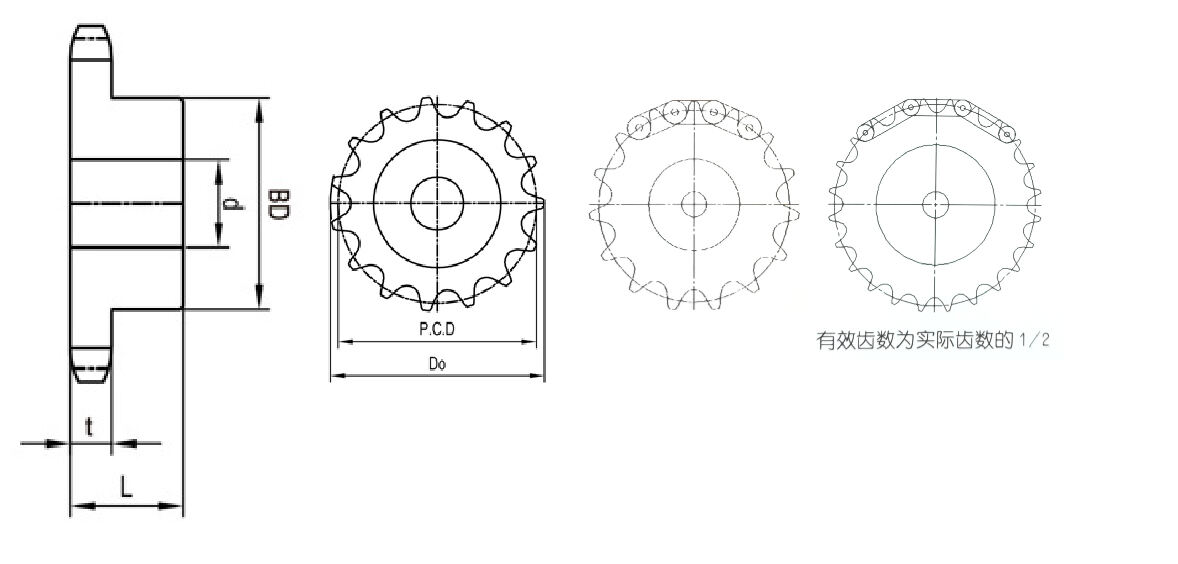

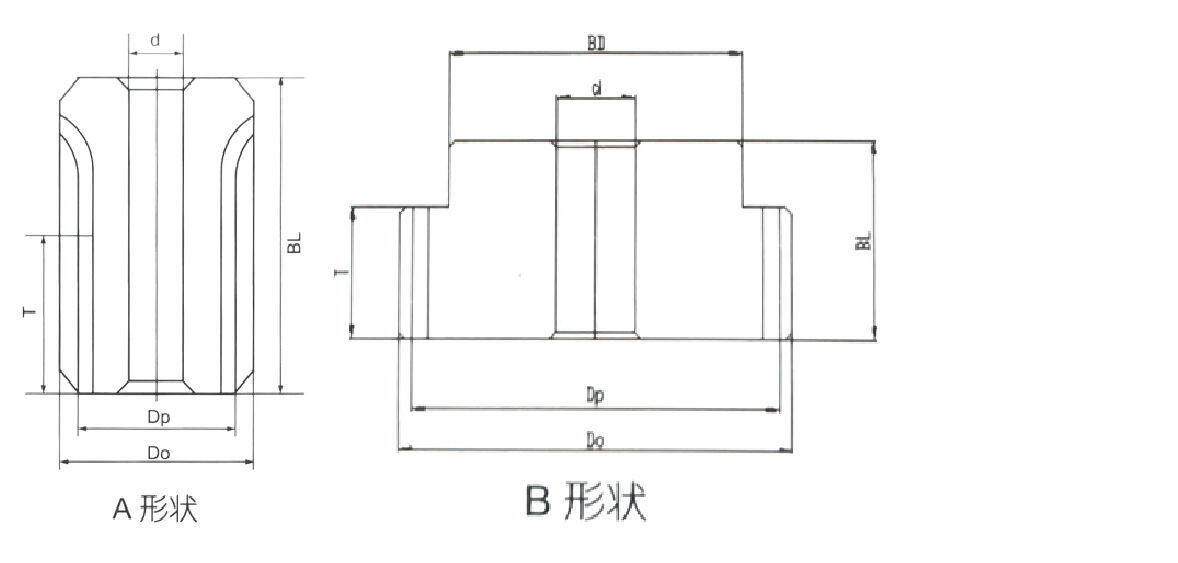

Double Pitch Chain Wheels

R-type roller chain sprocket: R-type roller chain sprocket is a double pitch sprocket with single cut teeth, S-type roller chain sprocket: this type of sprocket is a double pitch sprocket with variable cut teeth. The number of teeth of this type of sprocket is certain, and for every rotation of the sprocket, the chain will close with one of the two neighbouring teeth, which is defined as the number of "working teeth". In the case of an odd number of teeth, the sprocket rotates twice so that each tooth engages with the chain once, which prolongs the life of the sprocket.

Double speed sprocket

Idler pulleys

Idler pulleys maintain proper tension during the transmission of roller chains. Hardened sprocket teeth provide excellent durability for smooth and quiet rotation.

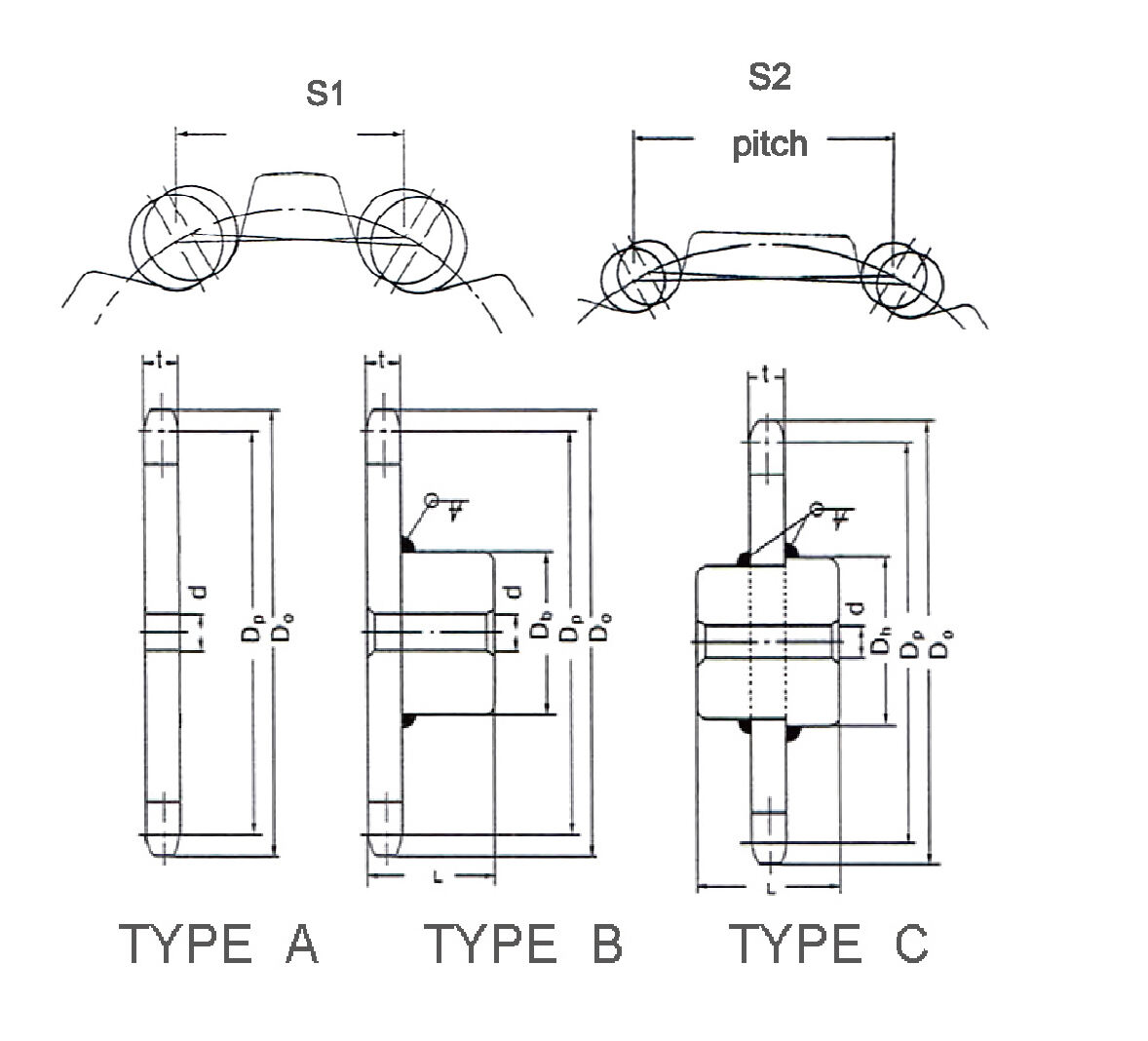

Conveyor Chain Sprockets

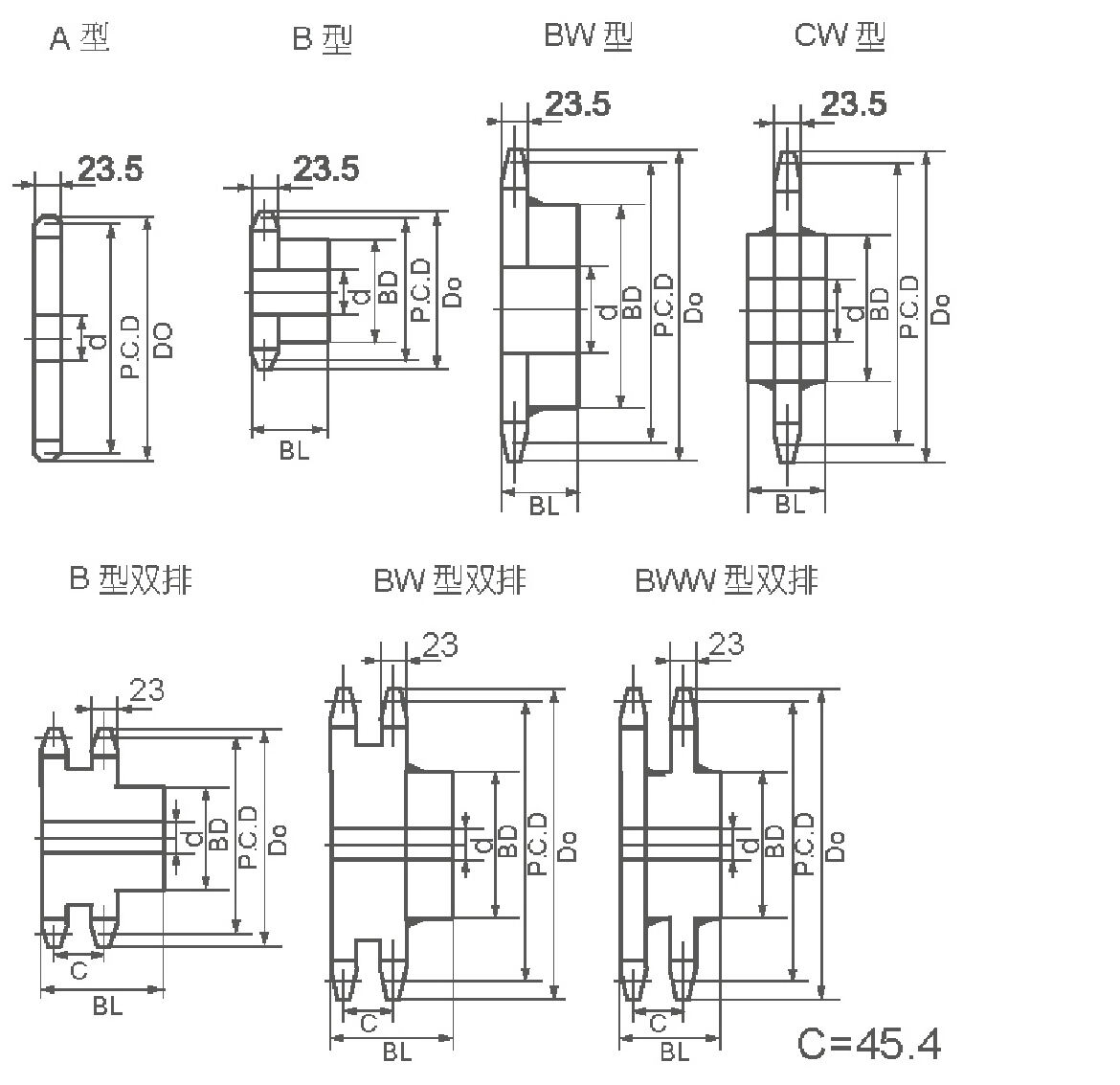

Conveyor chain sprocket is processed by milling technology of machining centre, special tooth profile is designed to minimize roller activity and allow smooth normal reverse direction movement, conveyor chain sprocket stock is divided into A, B, C type, A type with special cam can be welded very quickly to the required type of sprocket, such as the need for high-strength, high wear-resistant sprocket, the teeth can be heat-treated according to the requirements.

Spur Gear

Spur gears are gears that drive between two parallel shafts and are the most common gears. Because the tooth flanks are parallel to the axes of the assembled shafts, spur gears do not generate thrust (axial force) in transmission.

In addition, because spur gears are easy to machine, it is possible to create gears with high precision.

Bevel gear

Preessure angle20*

Stainless steel sprocket

Made of high quality 304 stainless steel, high hardness, high temperature resistance and corrosion resistance.

EN

EN

AR

AR

HR

HR

DA

DA

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

SR

SR

SK

SK

UK

UK

VI

VI

TH

TH

TR

TR

AF

AF

MS

MS

IS

IS

HY

HY

AZ

AZ

KA

KA

BN

BN

LA

LA

MR

MR

MY

MY

KK

KK

UZ

UZ

KY

KY